Введение

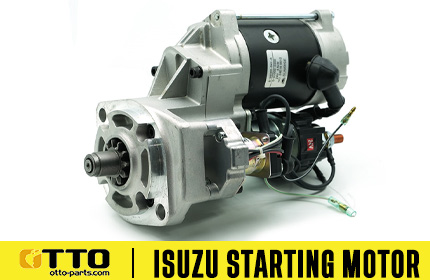

For owners of

Isuzu 6BG1

and

6BG1T

engines, the

1‑81100338‑1 starter assembly

is a compact yet vital part. It is responsible for converting the battery’s electrical energy into the mechanical force needed to crank the engine. This starter is a direct-fit option for a wide range of heavy-duty applications, including Hitachi EX200‑5/6, ZX200, ZX240, Sumitomo SH200‑3, SH300, Kobelco SK200‑6, and various Sany, Liugong, and Xuzhou construction machines that utilize the 6BG1 series engine. A high-quality, correctly specified starter ensures reliable starts, protects the engine, and minimizes downtime. This article will explore the role of the 1‑81100338‑1, the engineering behind it, common failure modes, and how to choose and maintain the right unit for your machine

The Role of the 1‑81100338‑1 in the 6BG1 Engine

The 1‑81100338‑1 is a 24V, heavy-duty 4.5kW, 11-tooth starter motor, commonly produced by NIKKO and other specialized suppliers for Isuzu. It is engineered to meet the high-torque demands of the 6BG1/6BG1T, a 6.5L inline-six diesel engine known for its durability and high torque output of 368–412 Nm at around 1600 rpm.

The starter assembly consists of three main parts:

-

Electric Motor: A powerful DC motor that generates the initial cranking torque.

-

Starter Drive (Bendix): A mechanism with a one-way clutch that engages the starter pinion with the flywheel to turn the crankshaft and disengages once the engine starts.

-

Electromagnetic Solenoid: A switch that, upon receiving a signal from the ignition, pushes the pinion into mesh with the flywheel and simultaneously connects the motor to the battery.

This process must deliver enough torque to overcome the engine's compression, even in cold conditions or after long idle periods, making the quality of the starter assembly critical for uptime.

Why Quality Matters for the 1‑81100338‑1

The 6BG1 engine is renowned for its reliability in demanding applications. To maintain this standard, the starter must be robust enough to handle high starting currents and frequent use. Key quality factors include:

-

Power and Speed: The 24V, 4.5kW specification is designed to provide ample torque for the 6BG1’s high compression ratio.

-

Durable Construction: Components like the commutator, brushes, bearings, and gears must be made from high-grade materials to withstand heat, vibration, and high currents.

-

Precision Manufacturing: Correct tooth profile, shaft end play, and solenoid travel are essential to prevent damage to both the starter and the flywheel.

Using a low-cost, poorly made imitation can lead to repeated failures, damage to the flywheel ring gear, and costly downtime, negating any initial savings.

Common Symptoms, Causes, and Fixes

Diagnosing starter issues involves a logical process of elimination, starting with the power source and moving to the starter itself.

1. Engine Cranks Slowly or Fails to Crank

-

Possible Causes: A weak or discharged battery, high resistance in cables or connections, a failing solenoid, or internal wear in the motor (e.g., shorted windings, worn brushes).

-

Troubleshooting Steps:

-

Measure the battery voltage (should be 24V+ for a 24V system).

-

Clean and tighten all battery and starter connections.

-

If the battery and cables are good, perform a voltage drop test on the main power circuit.

-

If voltage at the starter is low, the issue is likely in the circuit. If voltage is good but the motor is slow, the starter itself is faulty.

2. Clicking Sound, but No Crank

3. Grinding Noise During Start

4. Intermittent Starting (Sometimes Works, Sometimes Doesn’t)

Smarter Buying and Sourcing Decisions

When sourcing a

1‑81100338‑1 starter

, consider the following:

-

Verify Compatibility: Double-check the part number against your engine’s serial number and application.

-

Choose a Reputable Supplier: Look for suppliers with experience in Isuzu parts and positive customer feedback.

-

Consider the Core Exchange: If cost is a concern, inquire about exchange programs, but ensure the replacement unit's quality.

-

Balance Price and Quality: While a lower price is tempting, the total cost of a failed starter (including tow bills and lost productivity) often exceeds the price of a quality unit.

Conclusion

The

Isuzu 1‑81100338‑1 starter assembly

is a critical component that ensures the reliability of your 6BG1 or 6BG1T engine. By understanding its function, recognizing the signs of failure, and following a logical diagnostic and maintenance process, you can protect your equipment, reduce downtime, and maximize your return on investment. Choosing a high-quality, correctly specified starter is not just a purchase; it is an investment in the long-term performance and profitability of your machine.